halstrup-walcher is your specialist partner for mechatronic drives and high precision pressure measurement technology. We already supply our products to many well-known customers from a wide range of industries and applications. They appreciate our dedication to quality, punctuality and keeping costs under tight control. Our company is certified in accordance with ISO 9001 and ISO 14001 and we are constantly improving through our lean management programme. Together with you, we also develop suitable solutions for format changeover, retooling your machines and measuring the smallest pressures in non-aggressive gases. From the idea to the finished product, everything comes from a single source.

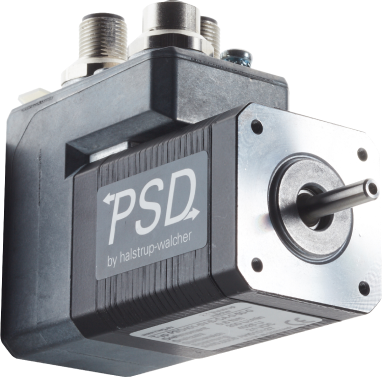

Experience drive technology

We offer both standardised and customised systems for format adjustment and changeover of your machines.

Feel measurement technology

We offer both standardised and customised products for

We love quality and processes

Lean management plays a very decisive role at halstrup-walcher. We discovered early on that lean and individual processes not only reduce costs, but also satisfy our employees and customers. Avoiding waste is the central theme of lean management, in which all employees participate. We transfer this mindset to our customers.

In addition, we use tools such as Shopfloor Management, 5S & One Piece Flow to optimise our processes even further.

halstrup-walcher is a medium-sized family business

Our strong focus on quality and lean makes us a professional partner. No matter whether you are a customer, employee or supplier: each person is valued at our company. For us, this means partnership and social responsibility.

Employee comments

Become part of our team

At halstrup-walcher, you benefit from flexible working hours and a lean management culture, characterised by short decision-making processes and an innovative suggestion scheme.