Industry 4.0

We are prepared: Our understanding of the production of the

Individuality and flexibility are increasingly important for manufacturing companies. Year after year, they face growing pressure to produce new production formats at very short notice and to adapt flexibly and quickly to changing customer requirements. The ability to switch quickly from one product format to another is a decisive factor in remaining competitive.

Industry 4.0 and cyber-physical systems

A key aspect of Industry 4.0 is the networking of machines, operating resources, tools, storage systems and the resulting products with each other in order to make all processes run smoothly while offering high flexibility.

This network of manufacturing participants connected by IT systems is also described as the Internet of Things. A networked factory is called a “smart factory”. All material manufacturing participants exist not only in the real manufacturing world, but also in a virtual image that mirrors the real world in the Internet of Things and adds further information.

Any manufacturing participant that has a virtual image and can be networked to interact with other manufacturing participants is called a cyber-physical system (CPS). It is the unification of reality and its virtual image and the next step in the development of mechatronics into a symbiotic system that networks all the components in a system via information technology .

The self-retooling machine

Our positioning systems for format changeover in the machines of tomorrow

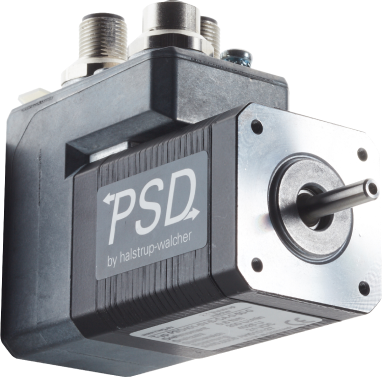

Ideally, the machines of the future could be a combination of cyber-physical subsystems. Positioning systems for format changeover, with their sensors (absolute encoders for determining position) and actuators (gears, motor, motor control unit) for moving the positioning objects, together with decentralised on-board intelligence (embedded system), provide all the components required for an independent cyber-physical system (CPS).

The CPS positioning system can, of course, be integrated into the machine processes in the traditional way: after the next target position has been specified (by the control unit), the CPS automatically moves to the new position while minimising the “drag error” (deviation from the intended position during the run).

If the drag error is too large, the positioning systems themselves make a situational distinction as to whether this is due to an obstruction and braking is required, or whether it is due to detected dirt or stiffness and the positioning movement must be accelerated in order to pass through the contamination.

This ensures that the positioning task is performed with the optimum result– but it is requested by the control unit. In the future, in the spirit of Industry 4.0, the control unit should instead focus on optimally supporting the role of the machine as a CPS by communicating with internal transport systems, neighbouring machines and the parts supplier.

Outlook for tomorrow's retrofit

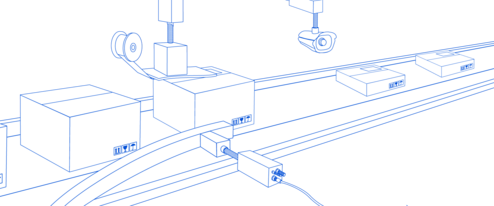

Alternatively, the positioning system can be integrated as a CPS by subverting the hierarchical structures of the machine control unit. Instead of relying exclusively on a vertical exchange of information with the machine control unit, the CPS positioning system communicates directly with decentralised components. For example, an optical sensor in a packaging line can detect that a new product format requires a changeover to a different packaging size.

The sensor provides the new target positions directly to the positioning systems, which then move the guide rail, the packaging tools and, if necessary, the inspection camera to the new position. The actual positions are continuously communicated to the higher-level machine control unit and also to the human operator at their panel, together with messages to facilitate preventive maintenance.

The ability to master retooling will be a decisive factor in determining the competitiveness of machine builders over the coming years.

Issues that used to be of interest only to the large corporations in the industry are now also becoming the focus of attention for small and medium-sized mechanical engineering companies. Thus, the future of CPS has long since begun – not only in terms of machines, but also of components.

More application reports

Our engineering

Are you looking for a custom-fit

Our drives

We are specialists for individual positioning systems and drive solutions.

Get to know our product variety.